How Formula 1 cars are made

- Racing Statistics

- Aug 31, 2025

- 4 min read

Formula 1 is more than a sport—it’s an engineering war fought in milliseconds and microns. Teams collectively spend over £1.5 billion a year to design and build just 20 cars, relying on nearly 4,000 of the world’s brightest engineers. Their pursuit? Shaving fractions of a second off lap times.

This obsession creates machinery that pushes the boundaries of what is physically possible: pistons surviving 20,000 RPM, gearboxes shifting in 2 milliseconds, and brakes hotter than lava. This article takes you behind the scenes—into the factories, testing rigs, and workshops where the impossible becomes reality.

How Formula 1 Cars are Made!

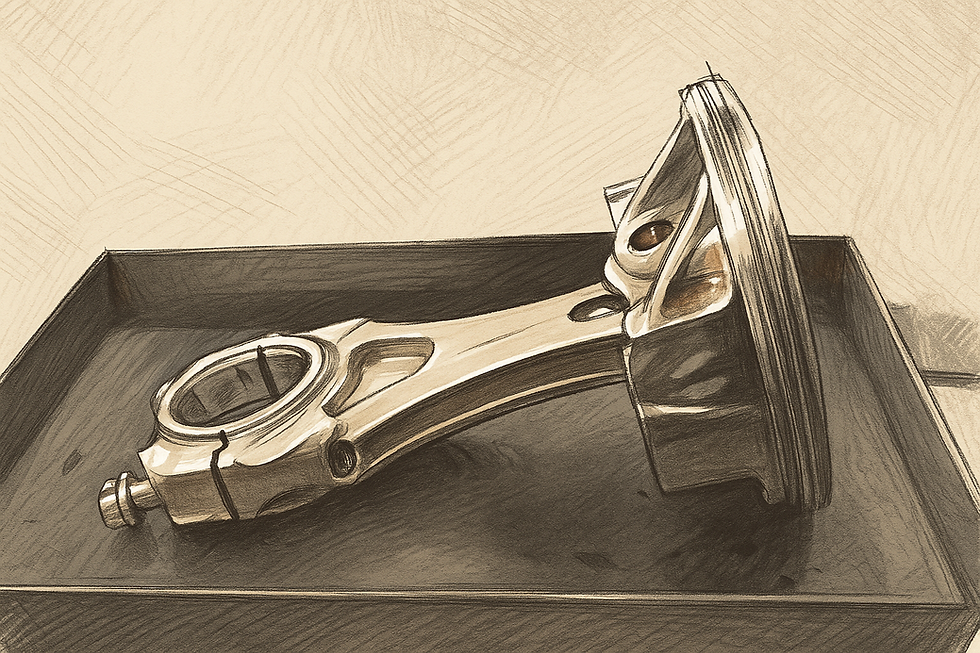

1. The Piston: £50,000 of Perfection

1.1 Design and Simulation

A single F1 piston costs over £50,000 when accounting for development. At Cosworth, the design process starts months before metal is touched. Engineers decide engine architecture (V6, V8, V10), bore and stroke, and valve positioning—parameters that affect every piston detail.

The piston crown—the surface facing combustion—is obsessively optimized using CFD simulations to ensure efficient fuel burn and minimal stress. Stress tests and safety factors are based on decades of database knowledge.

Watch the documentary or keep scrolling for the summary!

1.2 Forging and Machining

Each piston begins as an aluminium billet, heated to 500°C and forged into shape. Forging aligns the metal’s grain with the piston geometry, giving it superior strength. After forging, it undergoes T6 heat treatment to restore maximum hardness.

In machining, tolerances shrink to the unimaginable: grooves cut within 10–20 microns (0.01mm). CNC machines, costing hundreds of thousands, work in climate-controlled rooms where a few seconds of exposure to air can distort the part.

1.3 Counterintuitive Engineering

Pistons are not perfectly round—they start slightly oval so they become circular when deformed under stress.

The pin bore is deliberately curved to account for flex under combustion loads.

Quality control involves UV dye testing for microscopic cracks.

Finally, some pistons receive a diamond-like carbon (DLC) coating for wear resistance before joining engines tested at 1.5× normal life on dynos. Despite the cost, pistons are discarded after just a few thousand miles.

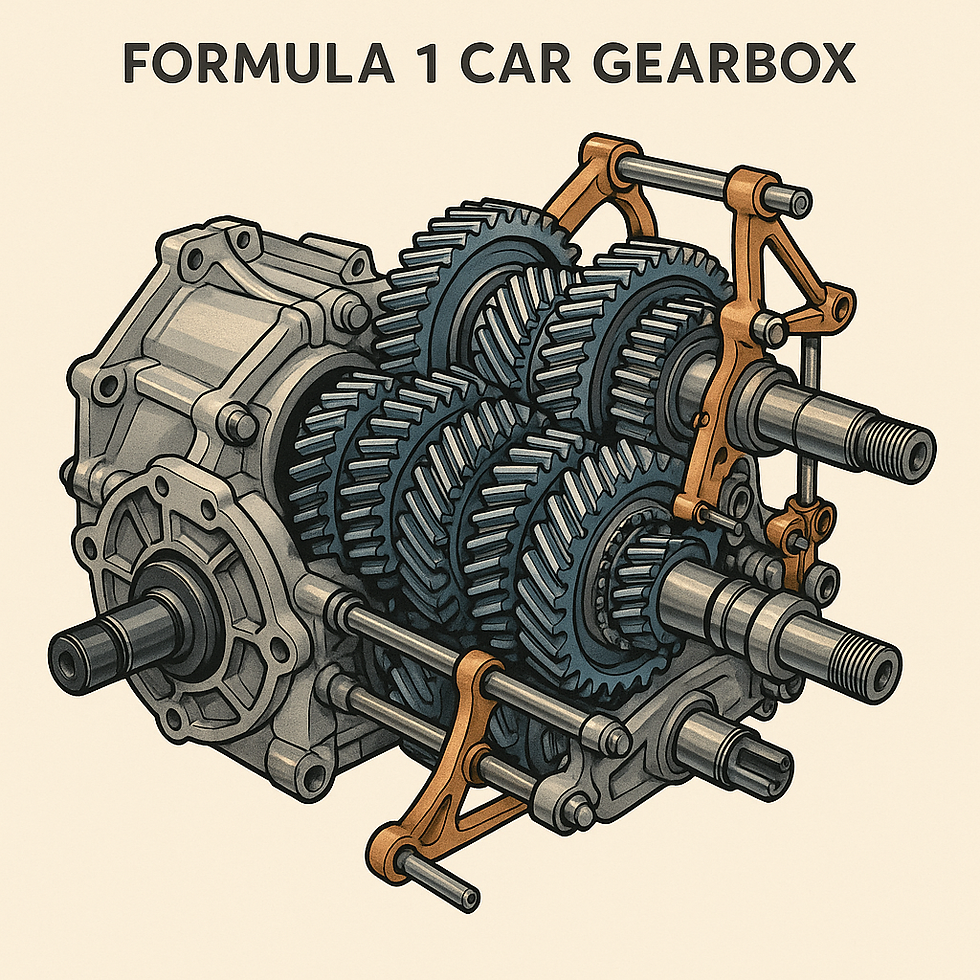

2. The Gearbox: £250,000 of Structural Genius

2.1 More than a Transmission

An F1 gearbox, costing £250,000, weighs only 40kg but holds 500+ components. Crucially, it acts as a stressed member: the suspension, rear wing, and crash structure bolt directly onto it. Without the gearbox, the car would split in half.

2.2 Engineering Challenges

Transparent development casings allow teams like Alpine to study oil flow, ensuring every gear stays lubricated.

Casings combine 3D-printed titanium with carbon patches to save grams.

Gear ratios are fixed for the season, unlike past eras when teams could adjust per track.

2.3 Seamless Shifts

Modern F1 gearboxes use dual selector barrels to engage the next gear while still locked in the current one. This results in shifts as fast as 2–4 milliseconds—thirty times faster than a blink. But if two gears engaged simultaneously, the gearbox would instantly explode.

2.4 The Differential

The differential includes hydraulic clutches that dynamically control wheel slip. This balances traction through corners while handling 1,000 horsepower—all inside a unit that must survive about 3,000 miles before replacement.

3. Brakes: Controlling Fire

3.1 Extreme Demands

Brakes cost ~£100,000 per car but must repeatedly stop it from 200 mph to 60 in just 3 seconds—producing forces up to 6g. Temperatures climb past 1,000°C, yet drivers depend on them corner after corner.

3.2 System Design

Brake-by-wire at the rear balances regenerative braking from the hybrid unit.

Custom carbon-fiber brake pedals withstand 180 kg of driver force and are molded to each driver’s foot.

Aluminium-lithium calipers are machined from solid blocks to remove weak points.

3.3 Carbon-Carbon Discs

Manufactured by Brembo, discs take 3 months to produce:

Carbon fiber needling aligns fibers for heat resistance.

Carbonization and methane infiltration transform them into dense carbon-carbon.

Precision machining drills up to 1,200 cooling holes, each exactly 3mm wide.

Discs wear just 0.01 mm per kilometer, meaning they can last multiple race weekends despite the extreme stress.

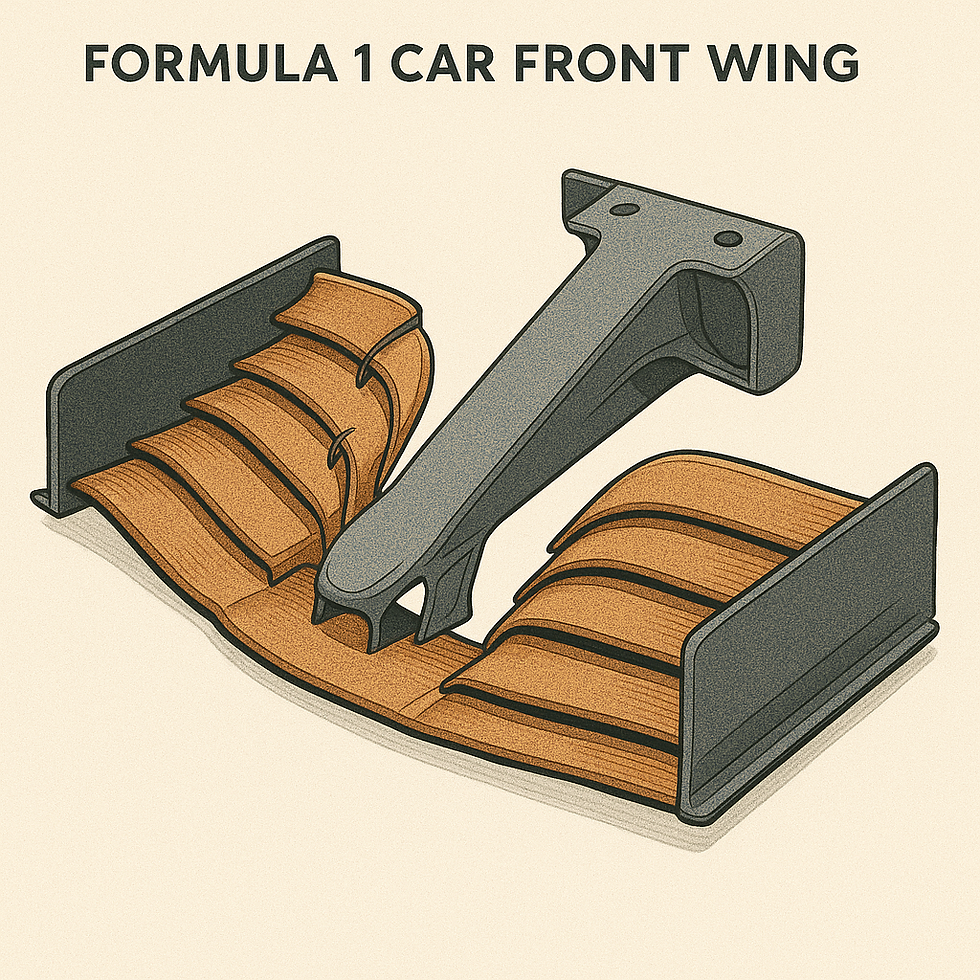

4. Aerodynamics: The Seven-Day Wing

4.1 The Front Wing’s Role

The front wing is the car’s aero conductor, setting up airflow for everything behind it. Teams spend seven continuous days producing a single wing, which can make or break a car’s performance.

4.2 From CAD to Carbon

Designs begin in CAD and are validated in CFD simulations.

Wind tunnel time is limited, so each test must count.

Composite engineers then use finite element analysis to balance strength with minimal weight.

4.3 Manufacturing

Carbon fiber layers are laser-aligned, bagged, and cured in an autoclave.

One misplaced ply can ruin an entire week’s work.

Finished wings undergo FIA crash tests and strength validation before hitting the track.

5. Suspension: Balancing Aero and Comfort

5.1 Why Suspension Matters

Suspension isn’t just about bumps—it keeps the floor-to-track gap optimal for downforce. Too soft, and the car bottoms out. Too stiff, and it becomes undriveable.

5.2 Key Components

Carbon wishbones double as aero elements and house Kevlar wheel tethers.

Push rods/pull rods translate vertical forces into rockers. Rear suspensions often use pull rods to free airflow over the gearbox.

Torsion bars replace bulky coil springs for packaging efficiency.

Heave springs manage massive downforce loads without destroying the chassis.

Anti-roll bars keep the car flat through corners.

Conclusion: Engineering Beyond Limits

Every part of a Formula 1 car—whether a £50,000 piston, a £250,000 gearbox, or a £100,000 brake system—is designed at the edge of physics. Nothing is overbuilt - how formula 1 cars are made is perfected. Nothing lasts longer than necessary. Every micron of precision, every gram of weight saved, every millisecond gained is the product of thousands of engineers working towards one goal: to go faster.

Formula 1 is not just racing—it is the pinnacle of human engineering obsession.

Find out what is the secret to McLaren Dominance this season!

Comments